S2K Commerce - Products Dropdown

- ${title}

S2K Commerce - Shopping Cart

- ${title}

S2K Commerce - Order Entry

- ${title}

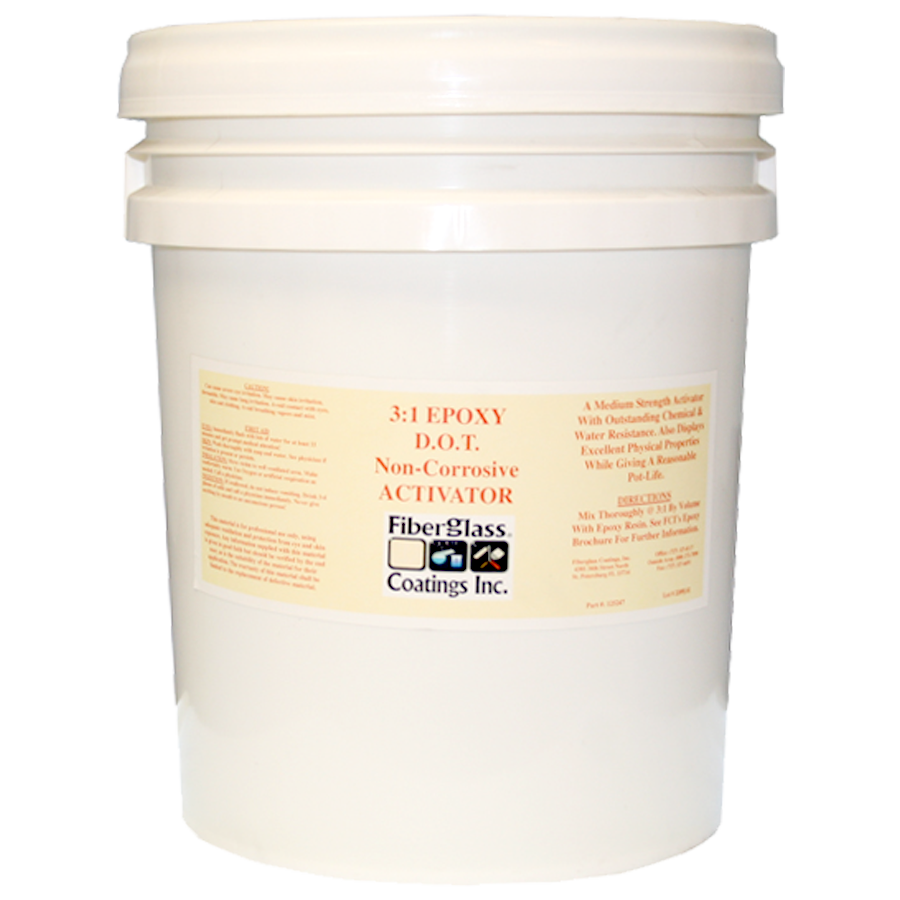

As with all adhesive compounds bonding surfaces should be

clean and free dirt or grease.

Our 3 to 1 Epoxy Activator forms an

easy to use 2 component 100 % solids epoxy system when mixed with either of our

available epoxy resins in a ratio of three parts Resin ( A side ) to one part

Activator (B side ) by volume. It Is significantly faster setting then our 2 to

1 system with improved chemical and solvent resistance and generally improved

physical properties. When mixed with our Standard Epoxy Resin it forms a

thicker high viscosity system more suited to adhesive bonding and casting

applications as it will generally form a tougher stronger plastic with better

adhesion and very good resistance to hydrocarbon fuels and ethanol. When used

with our Laminating Epoxy Resin it will form a thinner liquid more appropriate

for wetting out fiberglass and other reinforcements it will have a slightly

longer Gel Time and form a plastic with more flexibility, slightly less solvent

resistance and lower HDT. Both systems cure to a tough, hard, blush free, amber

colored plastic, with good physical properties, chemical and solvent

resistance, excellent resistance to water and good adhesion to wood, glass,

metals, and most other plastics.

As with all adhesive compounds bonding surfaces should be

clean and free dirt or grease.

Our 3 to 1 Epoxy Activator forms an

easy to use 2 component 100 % solids epoxy system when mixed with either of our

available epoxy resins in a ratio of three parts Resin ( A side ) to one part

Activator (B side ) by volume. It Is significantly faster setting then our 2 to

1 system with improved chemical and solvent resistance and generally improved

physical properties. When mixed with our Standard Epoxy Resin it forms a

thicker high viscosity system more suited to adhesive bonding and casting

applications as it will generally form a tougher stronger plastic with better

adhesion and very good resistance to hydrocarbon fuels and ethanol. When used

with our Laminating Epoxy Resin it will form a thinner liquid more appropriate

for wetting out fiberglass and other reinforcements it will have a slightly

longer Gel Time and form a plastic with more flexibility, slightly less solvent

resistance and lower HDT. Both systems cure to a tough, hard, blush free, amber

colored plastic, with good physical properties, chemical and solvent

resistance, excellent resistance to water and good adhesion to wood, glass,

metals, and most other plastics.

As with all adhesive compounds bonding surfaces should be

clean and free dirt or grease.

Our 3 to 1 Epoxy Activator forms an

easy to use 2 component 100 % solids epoxy system when mixed with either of our

available epoxy resins in a ratio of three parts Resin ( A side ) to one part

Activator (B side ) by volume. It Is significantly faster setting then our 2 to

1 system with improved chemical and solvent resistance and generally improved

physical properties. When mixed with our Standard Epoxy Resin it forms a

thicker high viscosity system more suited to adhesive bonding and casting

applications as it will generally form a tougher stronger plastic with better

adhesion and very good resistance to hydrocarbon fuels and ethanol. When used

with our Laminating Epoxy Resin it will form a thinner liquid more appropriate

for wetting out fiberglass and other reinforcements it will have a slightly

longer Gel Time and form a plastic with more flexibility, slightly less solvent

resistance and lower HDT. Both systems cure to a tough, hard, blush free, amber

colored plastic, with good physical properties, chemical and solvent

resistance, excellent resistance to water and good adhesion to wood, glass,

metals, and most other plastics.

As with all adhesive compounds bonding surfaces should be

clean and free dirt or grease.

Our 4 to 1 Epoxy Activator

forms an easy to use 2 component 100 % solids epoxy system when mixed with

either of our available epoxy resins in a ratio of four parts Resin ( A side )

to one part Activator (B side ) by volume. It Is significantly faster setting

then our 3 to 1 system with the best chemical and solvent resistance and

physical properties. When mixed with our Standard Epoxy Resin it forms a

thicker high viscosity system more suited to adhesive bonding and casting

applications and will form a hard strong plastic with excellent resistance to

chemicals and solvents including hydrocarbon fuels and ethanol. When used with

our Laminating Epoxy Resin it will form a thinner liquid more appropriate for

wetting out fiberglass and other reinforcements it will have a slightly longer

Gel Time and form a plastic with more flexibility, slightly less solvent

resistance and lower HDT. Both systems cure to a tough, hard, blush free, amber

colored plastic, with good physical properties excellent chemical and solvent

resistance, good resistance to water and good adhesion to wood, glass, metals,

and most other plastics.

As with all

adhesive compounds bonding surfaces should be clean and free dirt or grease

Our 4 to 1 Epoxy Activator

forms an easy to use 2 component 100 % solids epoxy system when mixed with

either of our available epoxy resins in a ratio of four parts Resin ( A side )

to one part Activator (B side ) by volume. It Is significantly faster setting

then our 3 to 1 system with the best chemical and solvent resistance and

physical properties. When mixed with our Standard Epoxy Resin it forms a

thicker high viscosity system more suited to adhesive bonding and casting

applications and will form a hard strong plastic with excellent resistance to

chemicals and solvents including hydrocarbon fuels and ethanol. When used with

our Laminating Epoxy Resin it will form a thinner liquid more appropriate for

wetting out fiberglass and other reinforcements it will have a slightly longer

Gel Time and form a plastic with more flexibility, slightly less solvent

resistance and lower HDT. Both systems cure to a tough, hard, blush free, amber

colored plastic, with good physical properties excellent chemical and solvent

resistance, good resistance to water and good adhesion to wood, glass, metals,

and most other plastics.

As with all

adhesive compounds bonding surfaces should be clean and free dirt or grease

Our 4 to 1 Epoxy Activator

forms an easy to use 2 component 100 % solids epoxy system when mixed with

either of our available epoxy resins in a ratio of four parts Resin ( A side )

to one part Activator (B side ) by volume. It Is significantly faster setting

then our 3 to 1 system with the best chemical and solvent resistance and

physical properties. When mixed with our Standard Epoxy Resin it forms a

thicker high viscosity system more suited to adhesive bonding and casting

applications and will form a hard strong plastic with excellent resistance to

chemicals and solvents including hydrocarbon fuels and ethanol. When used with

our Laminating Epoxy Resin it will form a thinner liquid more appropriate for

wetting out fiberglass and other reinforcements it will have a slightly longer

Gel Time and form a plastic with more flexibility, slightly less solvent

resistance and lower HDT. Both systems cure to a tough, hard, blush free, amber

colored plastic, with good physical properties excellent chemical and solvent

resistance, good resistance to water and good adhesion to wood, glass, metals,

and most other plastics.

As with all

adhesive compounds bonding surfaces should be clean and free dirt or grease.

Our 4 to 1 Epoxy Activator

forms an easy to use 2 component 100 % solids epoxy system when mixed with

either of our available epoxy resins in a ratio of four parts Resin ( A side )

to one part Activator (B side ) by volume. It Is significantly faster setting

then our 3 to 1 system with the best chemical and solvent resistance and

physical properties. When mixed with our Standard Epoxy Resin it forms a

thicker high viscosity system more suited to adhesive bonding and casting

applications and will form a hard strong plastic with excellent resistance to

chemicals and solvents including hydrocarbon fuels and ethanol. When used with

our Laminating Epoxy Resin it will form a thinner liquid more appropriate for

wetting out fiberglass and other reinforcements it will have a slightly longer

Gel Time and form a plastic with more flexibility, slightly less solvent

resistance and lower HDT. Both systems cure to a tough, hard, blush free, amber

colored plastic, with good physical properties excellent chemical and solvent

resistance, good resistance to water and good adhesion to wood, glass, metals,

and most other plastics.

As with all

adhesive compounds bonding surfaces should be clean and free dirt or grease

Our 4 to 1 Epoxy Activator

forms an easy to use 2 component 100 % solids epoxy system when mixed with

either of our available epoxy resins in a ratio of four parts Resin ( A side )

to one part Activator (B side ) by volume. It Is significantly faster setting

then our 3 to 1 system with the best chemical and solvent resistance and

physical properties. When mixed with our Standard Epoxy Resin it forms a

thicker high viscosity system more suited to adhesive bonding and casting

applications and will form a hard strong plastic with excellent resistance to

chemicals and solvents including hydrocarbon fuels and ethanol. When used with

our Laminating Epoxy Resin it will form a thinner liquid more appropriate for

wetting out fiberglass and other reinforcements it will have a slightly longer

Gel Time and form a plastic with more flexibility, slightly less solvent

resistance and lower HDT. Both systems cure to a tough, hard, blush free, amber

colored plastic, with good physical properties excellent chemical and solvent

resistance, good resistance to water and good adhesion to wood, glass, metals,

and most other plastics.

As with all

adhesive compounds bonding surfaces should be clean and free dirt or grease

As with all adhesive type compounds proper surface preparation is essential for good bond strength, recoating of the material should be accomplished before the material is fully cured after which sanding and solvent wash may be necessary for good secondary bonding.

As with all adhesive type compounds proper surface preparation is essential for good bond strength, recoating of the material should be accomplished before the material is fully cured after which sanding and solvent wash may be necessary for good secondary bonding.

As with all adhesive type compounds proper surface preparation is essential for good bond strength, recoating of the material should be accomplished before the material is fully cured after which sanding and solvent wash may be necessary for good secondary bonding.