Z6_EL9QHKG10GPM20IJGE61AK10O0

Z7_P86CH0O0I0RF10IB06HRVQ0087

S2K Commerce - Products Dropdown

S2K Commerce - Products Dropdown

Z7_EL9QHKG10GPM20IJGE61AK10S5

S2K Commerce - Order Entry

S2K Commerce - Order Entry

**Due to the current situation with COVID-19, We are limiting orders to TWO BOXES, in an attempt to keep up with Demand and ensure every customer has some hand protection**

Thank you for your understanding!

Thank you for your understanding!

Item#:

128909

Manufacturer:

FGCI Website

Your Price:

0.06

Each

**Due to the current situation with COVID-19, We are limiting orders to TWO BOXES, in an attempt to keep up with Demand and ensure every customer has some hand protection**

Thank you for your understanding!

Thank you for your understanding!

Item#:

128903

Manufacturer:

FGCI Website

Your Price:

0.06

Each

Directions for Use:

Step 1: Choose the appropriate volume for your project. The type of fiberglass used will determine the amount of resin needed.

Step 2: Make sure to agitate or stir the product thoroughly before use.

Step 3: Mix in the MEKP, stirring thoroughly. Please refer to the Catalyst Concentration Chart for quantities.

Step 4: Thinner fiberglass can easily be wet through. To thoroughly wet out heavier materials, apply resin first to one side, then flip the glass over to wet out the other side. Use paint-style rollers to distribute resin quickly.

Step 5: Roll each layer with a glass roller to remove air. The fiberglass will go completely transparent when it is adequately wet.

Step 6: Add sanding aid (Product #123833) to the final coat to allow a full cure and a tack-free surface.

This item is temporarily unavailable.

Item#:

124017

Manufacturer:

FGCI Website

Your Price:

7.64

Each

Your Price:

3.57

Each

Your Price:

7.98

Each

Item#:

129711

Manufacturer:

FGCI Website

Your Price:

14.12

Each

Item#:

129300

Manufacturer:

FGCI Website

Your Price:

12.18

Each

Item#:

129301

Manufacturer:

FGCI Website

Your Price:

15.52

Each

Item#:

130718

Manufacturer:

FGCI Website

This item is temporarily unavailable.

Item#:

129751

Manufacturer:

FGCI Website

Your Price:

26.46

Each

Item#:

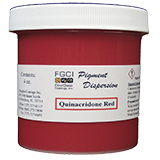

123954

Manufacturer:

FGCI Website

Your Price:

16.51

Each